Power Chucks Reconditioning

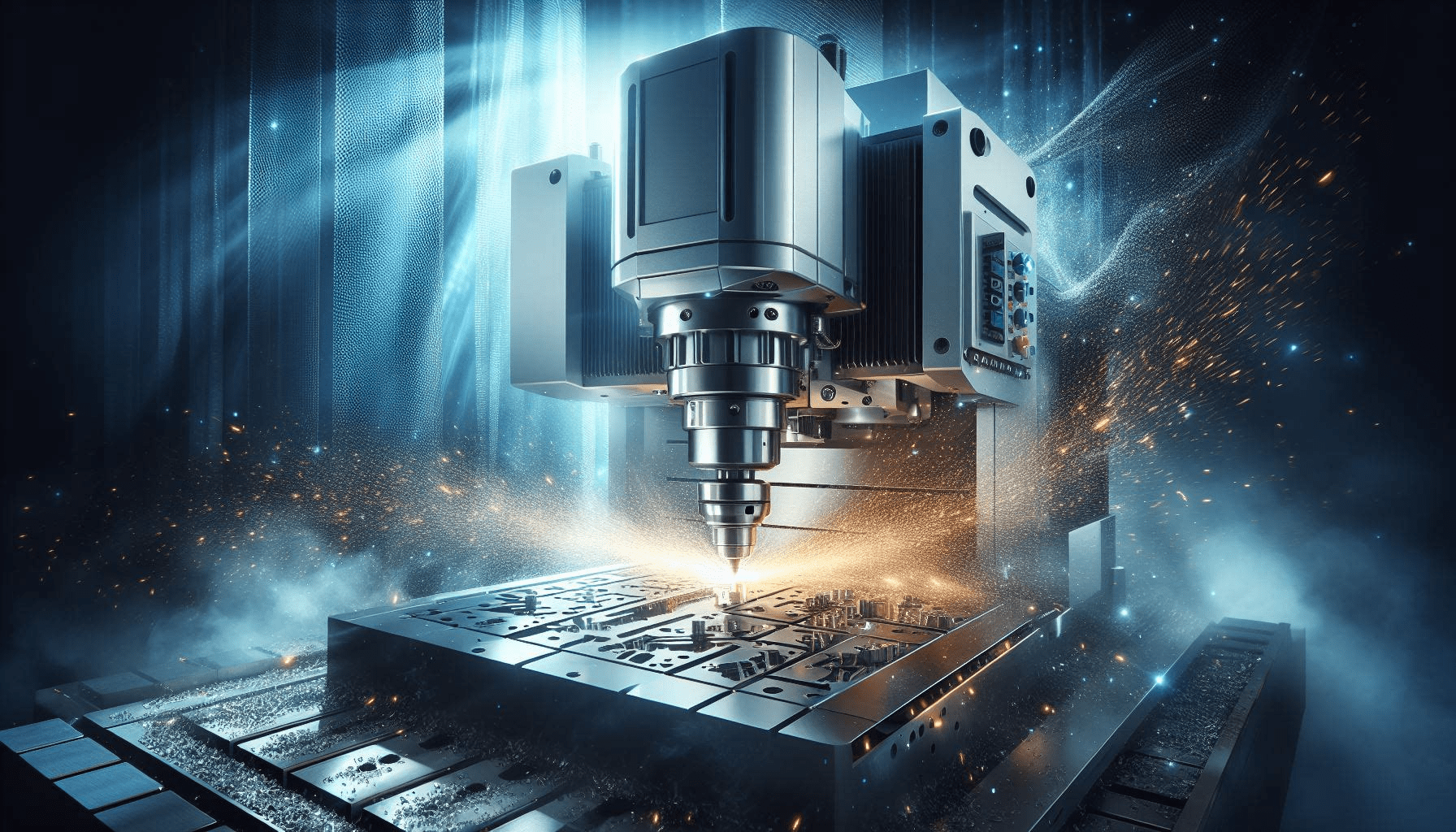

CNC Power Chuck Reconditioning

Our chuck reconditioning service could save you thousands of rupees compared to a new one. We have experience with all major chuck brands in all sizes and configurations.

Submit Enquiry

CNC Power Chuck Reconditioning

Our Chuck Reconditioning service will save you thousands of Rupees compared to a new one. We have experience with all major chuck brands in all sizes and configurations

Submit Enquiry

Product Details

Holding Capacity

Good

Model Name/Number

Yes

Number Of Jaws

4

Material

SS

Packing Type

Box

Plunger Stroke

16 mm

Country of Origin

Made In India

We are the leading manufacturer of Chuck Jaw, Hydraulic Chuck and also CNC lathe chucks and also of good quality.

reconditioning of power chucks - What To Expect!

- All major parts like master jaws and wedge will be replaced and old ones will be sent back.

- Grinding of chuck body slots to make them straight within 0.01 mm.

- Performance of chuck will be as good as new.

- Material EN353 will be used for master jaws and wedge.

- Warranty of two years against breakage of replaced parts.

- Special chuck Grease of Motul brand is being used.

Welcome to Brij Metal Works

About Us

We excel in CNC Power Chuck Reconditioning and provide hydraulic chucks for lathes. Our diversified product range includes power chucks, soft jaws, hard jaws, and more, tailored to your needs.

At BMW, we understand the importance of time. That’s why we pride ourselves on our ability to provide fast turnaround times, competitive pricing, and excellent customer service. We work closely with our customers to ensure that their parts and components are manufactured to their exact specifications.

In our quest for diversification, we’ve started manufacturing power chucks, soft jaws, hard jaws, and customised jaws for CNC turning centers/VMCs as per the needs of our customers. We maintain high accuracy and keep delivery commitments for customers across India.

We’ve also added numerous new projects like measuring gauges, work holding fixtures, and related items of CNC machines which includes timing belts, foot switches, new power chucks, reconditioning of chucks, and spares of FANUC system.

Join us on our journey towards precision and excellence.

Why Choose us

Decades of Experience

Unwavering Quality

Fast Turnaround Times

Excellent Customer Service

Competitive Pricing

Diversified Product Range

Commitment to Delivery

Leading manufacturer of Chuck

Products

Brij Metal Works Achieves ZED Bronze Award for Sustainable Excellence

Celebrate our remarkable achievement as Brij Metal Works proudly earns the ZED Bronze Award, a testament to our commitment to sustainability and excellence in the MSME sector

TESTIMONIAL